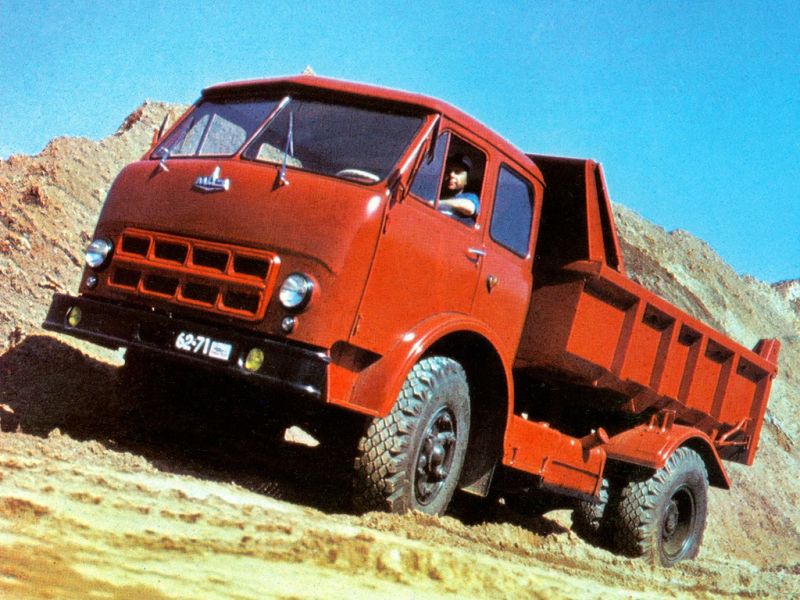

MAZ-503

The most popular of all modifications based on MAZ-500 chassis was of course the “503” model. The dump truck was designed and delivered to the conveyor back in the 70’s, but still copes well with its task. There were also special modifications: 503A and 503V with improved specifications. The whole model range is MAZ.

Car history

Minsk Automobile Plant progressively stamped the model after the model and their modifications. MAZ-503 was born as an upgrade from MAZ-500 version. Production took place in the period from 1966 to the middle of the 70s. In the jubilee year, 1970, the model was upgraded for Minsk plant. The main difference from the “500” model was the reduced wheelbase and narrow focus – dump truck. Formed frame sections were fastened with rivets.

It is located on four springs, respectively, arranged longitudinally. Besides, hydraulic shock absorbers working telescopically are introduced into the suspension. The properties of the cabin were changed in small parts, it was also completely made of metal and assembled by welding, in addition to three seats there is one sleeping place.

The tilting mechanism of the platform is equipped with a hydraulic system operating in reciprocating mode. It was convenient that tilting and other body control operations could be carried out from the driver’s cab. A special valve is integrated into the system, which after the shipment is completed activates the shaking of the load platform for better dump.

For convenience, the steering system is equipped with power steering. The changes also affected the transmission, with the main gear now having a higher gear ratio for the rear axle (9.57). The brake system applied only to the vehicle and did not have the capability to connect a trailer (the brake crane was of the ZIL type).

Interestingly enough, MAZ-503V had pneumatic control over the hydraulic system. The process is carried out under the control of pneumatic distribution crane. The cabin was provided with the same elements as in “five hundred” MAZ. Manual window lifters, electric windscreen wipers, rugs, boxes for tools and personal belongings. For convenience, even folding sun visors were provided. There is no need to mention rear-view mirrors.

Specifications

The differences between the modifications were mainly related to a few changes. Thus, MAZ-503V reworked and controlled hydraulics; MAZ-503A improved the characteristics of propulsion elements.

| Model | YAMZ-236 |

| Motor type | Four-stroke. Compression fire |

| Cylinder number | 6 |

| Cylinder arrangement | V-shaped at an angle of 900 |

| Cylinder operating procedure | 1 – 4 – 2 – 5 – 5 – 3 – 6 |

| Working volume | 11.1 liters |

| Compression degree | 16.5 |

| Maximum horsepower | 180 |

| Maximum revolutions | 2100 rpm |

| Mixing | Injection itself |

| Number of valves per piston | 2(inlet and outlet) |

| Starter type | ST-103 (24 watts) |

| Maximum speed on the horizontal section at full load | 75 km/h |

| Average fuel consumption | On 100 kilometers 22 liters of fuel |

| Transmission | |

| Coupling | Double disk dry friction |

| Gearbox type | Mechanics |

| Number of transmissions | 6(five forward and one back) |

| Synchrons | International 2-3 and 4-5 steps |

| Gearbox ratios | |

| First | 5.26 |

| Second | 2.90 |

| Three | 1,52 |

| Fourth | 1.00 |

| The fifth | 0.66 |

| Reverse | 5.48 |

| Total rear axle gear ratio | 8.28 |

| Dimensions | |

| Wheelbase | 3400 mm |

| Wheel formula | 4×2 |

| Rear wheel track width | 1865 mm |

| Beam width of front wheels | 1970 mm |

| Road clearance (before and after) | 270 mm |

| Length | 5785 mm |

| Width | 2500 mm |

| High- | 2650 mm |

| Turn radius | 8.5 m. |

| Bus size | 11-20 mm. |

| Lifting characteristics | |

| Cargo volume | 3.8/5.1 m3 |

| Carrying capacity | 8 tons |

| Weight of the car in full gear | 7 250 kg |

| Weight at full load | 15 250 kg |

| Maximum load on the front axle | 3580 kg |

| Maximum rear axle load | 10 tons |

In addition to the above characteristics of MAZ-503 dump truck had two headlights and two skirts. The headlights work in two modes: dipped beam and high beam. The dashboard and interior also had lighting. The G-271 generator (24 watts) provided the work of the power grid. As well as the whole series of models “500”, the big minus was a large amount of chemicals to be thrown away. This factor affected the environmental performance of the truck. At the moment MAZ-500 has the status of EURO-0.

Modernization and development

- MAZ-503 Experienced I – was developed in 1958 on the basis of the basic version of MAZ-300. The aim was to provide data for effective work in a career environment. This model as an exhibit is located in the Machine Building pavilion at the All-Russian Exhibition Center.

- MAZ-503 Experienced I – the next version received an updated bumper and upgrade of the power and technical characteristics. A prototype appeared in 1962.

- MAZ-503 – the main model was introduced in 1963 and was produced until the year 65 without any improvement.

- MAZ-503B – from 1965 to the beginning of the 70s – one of the most popular dump trucks. The upgraded model received a new straight-sided body. In addition, the opening of the tailgate was now automatically regulated.

- MAZ-503A – the appearance of the front part has changed again in comparison with the predecessor “B”. Electrical devices were replaced by more modern ones: heating furnace; lighting devices and others. The model was produced from 1970 to 1977 and was replaced by MAZ-5549, which was built on the same base, but with a wider processing of working systems.

The more trucks from Belarus, the more they increased their potential. The versatility of the basic models and their flexibility in conversion played a major role in the efficiency of the machines. It was important for one reason – the country needed good cargo transportation, and the Minsk Automobile Building Plant coped with these tasks.

Pluses and minuses

After a while, MAZ-503 has become obsolete, but has not lost its excellent working qualities. The model adopted the main list of advantages and disadvantages of its elder brother – 500th version of the truck. The dump truck demonstrates the following nuances:

- Good payload. When in working order, the machine can easily compete with modern trucks in this respect;

- Focused on the job. Up until the 90’s MAZ, the focus was on the maximum performance of the machine, but only after that were the solutions for the rest of the elements;

- Sleeping space will allow the driver to sleep in case of such a need, for example, when travelling long distances;

- Easy access to engine, gearbox and other machine systems. The cabin tilts out, allowing easy access to any part of the workpiece;

- Perfect tightness of the interior and almost no comfort. Without additional upgrades, the driver’s workstation leaves much to be desired;

- In cold weather, it’s even more uncomfortable to drive, only an additional heater can save you.

We sum up

In the presence of these or those qualities, the car still remains in history as a positive product of the Minsk Automobile Building Plant. Taking into account the love of drivers for modernization and improvement, any drawback or minus of the machine can be turned into a positive direction, it takes just a couple of hands.

The more trucks from Belarus, the more they increased their potential. The versatility of the basic models and their flexibility in conversion played a major role in the efficiency of the machines. It was important for one reason – the country needed good cargo transportation, and the Minsk Automobile Building Plant coped with these tasks.

We advise you to read the article: MAZ – history of Minsk Automobile Plant