ZIL-130

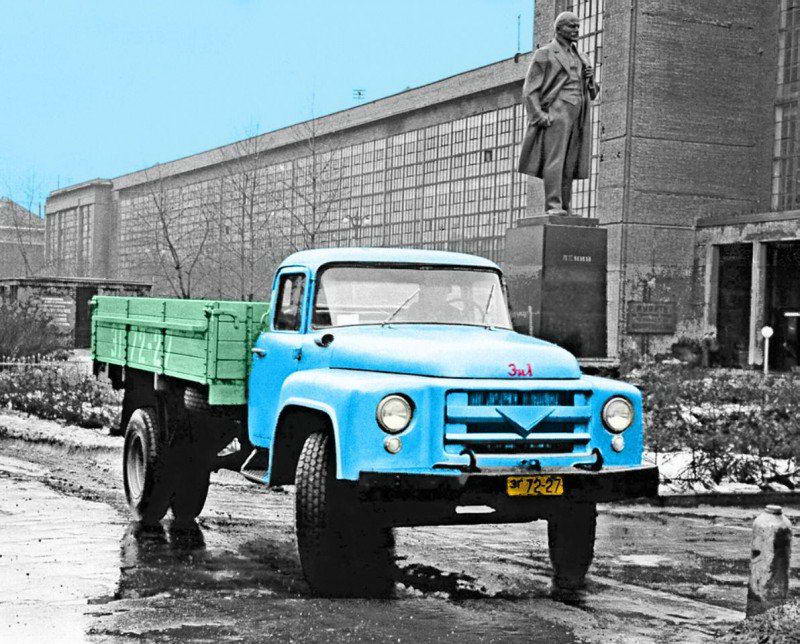

The legendary ZIL 130 model can be talked about for hours. It all began in the post-war years, when the Soviet Union needed equipment for agricultural needs. This Soviet and later Russian car came to replace the old model ZIL-164, which was initially produced as ZIS-150. Before the model became the same as we know it, there were a lot of changes in it. Before the restructuring of the Stalin plant, the model was produced as ZIS-125.

As a product of the Likhachev plant it was produced in the period from 1962 to 2010. Initially, the assembly was carried out in Moscow, but in the 90s the capacities were transferred to Novouralsk. There the car was produced under another name – the Amur. It is noteworthy that the ZIL-130 became the first truck of its kind, which began to be painted white and blue. Before that, all ZILs were painted khaki because they were made for military purposes. The whole model range is ZIL.

Appearance

The omnipresent versions of the ZIL trucks were extremely rare and raw. The excuse is weighty, it took a lot of machinery to compensate for the damage after the war. But in the end, already in 1956 the prototypes were much more beautiful than their predecessors.

After a number of changes, which concerned both the restyling of the truck and the plant itself, the ZIL-130 was presented at the annual international fair in Leipzig, where it received a gold medal, and engineers received many diplomas. Since then, the “130” model has been gaining unprecedented popularity.

The fact is that ZIL dump trucks had a lot of modifications. The most used of them were semi-trailers and articulated haulers. The most significant modifications were made in 1966 and 1977. On the basis of the usual “one hundred and thirtieth”, fire-fighting vehicles and cranes, tankers and vans, flatbed trucks and construction dump trucks were created. The truck is effective even in cramped urban conditions due to the turning radius of up to 7 meters. With a payload of only 3 tons, the ZIL-130 weighs at least 4 tons.

At the same time, it can be used to tow a trailer weighing no more than 8 tonnes. On the outside, the Russian truck looked very good for that time. The truck was able to attract attention to itself. It was painted white and blue. Before the ZIL-130, all the automotive companies worked only on the defense and army spectrum, based on this, the car had a protective coloring. The hood had an alligator type. ZIL received streamlined wings, panoramic windshield. In addition, the cabin had a ventilation hatch and windows.

The bodywork

The body was supplied with a folding tailgate and was considered to be a passenger and cargo body. Grilles on the sides were equipped with benches that could be folded back. They could accommodate 16 people. There was also a bench that could be taken off – it could accommodate 8 people.

The basic modification of ZIL-130 includes awning together with arcs, which can be removed and installed at any time. The body design also has practicality. The floor height of the cargo compartment of the ZIL-130 is similar to the floor height of railway wagons. This fact greatly simplifies the process of loading and unloading.

Additional equipment included light disguise for military versions, canisters, axe and shovel.

Salon

The ZIL-130 steering mechanism was a screw with a special spherical nut plus a piston-rail. The hydraulic booster was built in. The three-seater cabin is located just behind the engine. The seat is adjustable in length, height and inclination of the backrest. Among the basic options in the cabin was a heater, wiper with two brushes, a device for washing the glass. For the 60’s ergonomics of the cabin at the highest level. The dashboard and functional instruments are very comfortable for the driver.

Two ventilation hatches are provided in the cab roof. The grille has become a memorable element. The cabin was made of solid metal and was designed for three seats. The engineering staff worked for the glory, because the car was comfortable and was very disoriented from many Soviet trucks. Drivers received improved conditions for performing their work.

It was much more convenient to sit inside, because the changes also touched the width – it was increased by 1.2 meters, compared to the model ZIL-164. In the spacious cabin were optimally located devices and controls. In addition, there were soft seats – for the driver and for passengers (double). The driver’s seat could now be adjusted in horizontal and vertical directions.

It was also possible to change the angle of inclination of the backrest and cushion. It was on the ZIL-130 that the hydraulic power steering debuted. This not only improved the ease of operation of the truck, but also its safety – if the front wheel ruptured, the truck was easier to keep on the road.

Specifications

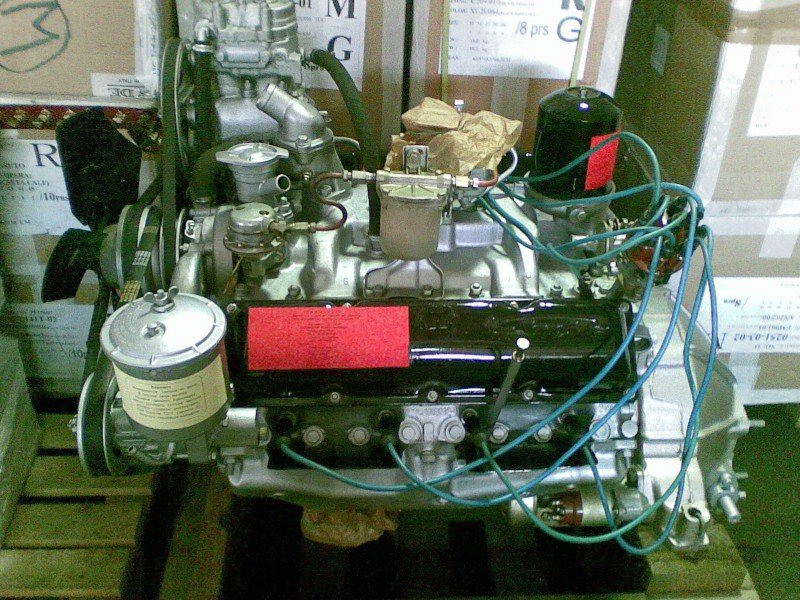

The ZIL-130 was originally equipped with an eight-cylinder 4-stroke engine with a power of 148 hp (3000 revolutions per minute). The working volume was 6 liters. The engine lubrication system was combined with spray and pressure. The engine power supply system is forced, the cooling system is liquid.

Suspension dependent, frame consisted of steel spars with five crossbars. The 1.5 hp starter was activated by means of a traction relay. Known to everyone, the ZIL-130 truck became a breakthrough in the Soviet engineering. Together with it, there were three-seater cabins, hydraulic power steering, control gears, which included helical gears and synchronizers, engine preheater, glass washers and others.

Powertrain

ZIL-130 purchased a power unit, which device had much in common with the motor from the modification of ZIL-111. It was a V-shaped eight-cylinder engine, but with a smaller working volume, which was designed for the already familiar at the time 76th gasoline. The engine came with a 2-chamber carburetor K-88AE, with a falling flow, balanced float chamber. There was a limit stop.

From the very beginning, an experimental type of motor was proposed, which was a carburetor motor with a V-shaped cylinder arrangement. The volume was 5.2 liters. This engine was able to develop up to 135 horsepower and 3200 rpm. The collapse of the cylinder block was 90 degrees. However, at the debut tests it became clear that such capacities would be lacking and the ZIL-130 truck simply could not get good dynamics.

At that time, work was started on using 8 cylinders in the same V-shape. Such improvements allowed to increase the engine power up to 150 horses. Then it was decided to curtail the production of 6-cylinder units. The new engine allowed the vehicle to reach a speed of up to 90 km/h. The valve arrangement on this 4-stroke engine was at the top. The engine volume was 6.0 liters and 3,000 revolutions.

In 1974, it was decided to use a more economical engine type for some models. Thanks to this replacement, the efficiency of the truck was also improved. This unit was the ZIL-157 with 6 cylinders in series, with a power equal to 110 horsepower. The engine was powered by gasoline A-72.

The device used an economizer design and a mechanical pump to speed up. It is equipped with a pneumatic crankshaft speed regulator, which is centrifugal. The engine is lubricated in a combined cycle. In practice, this is done by means of pressure, spraying oil. At the initial stage, this mechanism included a device for deep filtering. It looked like a set of thin plates made of steel. A jet-powered centrifuge was used for increased cleaning.

The fuel pump provided for forced feeding of the motor. It was designed according to the B-9 diaphragm type with a single outlet valve and a pair of inlet valves. The crankcase blower function has a closed type. 2-stage air purification is carried out with the help of the filter BM-16. The given engine was quite voracious – on hundred it could eat from 30 – 40 litres. It is clear that at that time it was not a problem, as the fuel was worth a penny. But today, many truck owners had to remake their cars in order to reduce the cost of their operation. A full 170-liter tank was only enough for 445 kilometers.

By the end of the 1980s it became clear that it was extremely irrational for trucks to drive on gasoline. In order to move the ZIL to cheaper fuel, all the forces were thrown at the new modernization of the engine. But unfortunately, the tests and prototypes did not go any further.

Transmission and clutch

The car has a rear-wheel drive axle, uses a dry clutch with one disc and mechanical, with a pair of synchronizers (2-nd and 3-rd and 4-rd and fifth gears), five-speed gearbox with a permanent gear hook, except for the 1-st and rear gears. This node was a new one in the automotive industry and has been improved. The gearbox transmits the torque from the engine to the rear axle by means of a PTO shaft. The standard 130th and elongated had two shafts with an intermediate support, which was attached to the frame.

And the short-base model was supplied with a single shaft that did not require an intermediate support. The manual gearbox was designed in 1961. Already 6 years later, in 1967, the gearbox design underwent minor changes – it was expected and it happened, the appearance of the front bearing for the driven shaft, the shaft neck changed its design. The needle roller bearing was replaced by a cage.

There was no locking ring in the restyling box. In order to prevent water from entering the gearbox when the machine is fording or in time for heavy rainfall, the gearshift handle has been insulated with a rubber seal that resembles a case and clamp.

A special paste allowed manufacturers to protect the gearbox cover and hatches, oil sump surface and other parts of the device. Inside, everything is ventilated with a ventilation tube. The box crankcase itself was made of the best cast iron, which significantly increased its service life. Hydraulic shock absorbers are used on the front axle, and telescopic type on the rear axle.

Brake system

On the truck ZIL-130 are installed on all wheels of drum-type brake. They function under the influence of pneumatic system. The air reserve is kept in a specialized tank under the pressure, which is provided by the compressor of the mechanical type. It is operated by the belt water pump pulley.

Work of the 2-uh cylinder compressor is equal to 2000 revolutions per minute that makes 220 litres per minute. It has liquid cooling. The number of air cylinders is 2 pieces of 20 liters each. Parking brake also uses a drum, which blocks the cardan shaft.

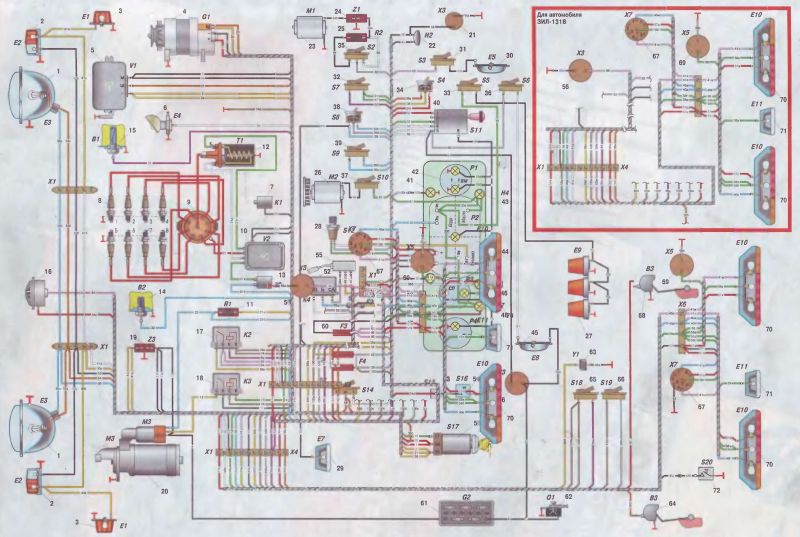

Electrical system

The voltage of the electrical system is 12-volt. Power supply is made from the accumulator of type 6ST-90-EM. The number 90, in the name indicates the amount of AmCh. Generators were of two types: the most common one was 32.3701 (it can be found also on trucks of other manufacturers, for example, KamAZ), it provides current of 60 amperes; for ZIL-157D it was supplied with G108-V 60A power.

The voltage regulator is РР350-А(3702), contactless, semiconductor. Starter – ST130-AZ, is found not only in the production of ZIL. The distributor of ignition – Р-137, with automatic regulation of advance of ignition through centrifugal vacuum regulators. The ignition coil is B114-B. Candles of ignition – А11 with carving М14*12,5.

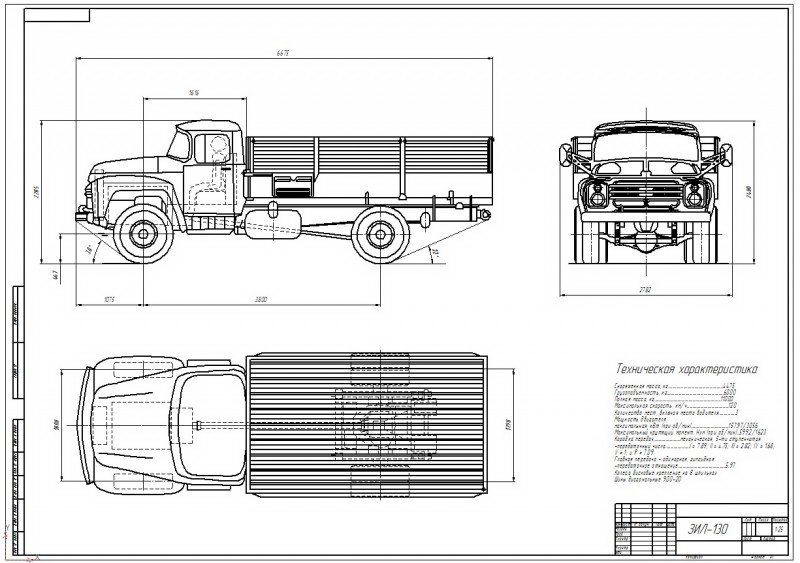

Dimensions

Dimensions of ZIL-130 dimensions are as follows: length – 6 672 mm, width – 2 500 mm, height – 2 400 mm. Clearance – 275 mm. Wheelbase – 3 800 mm. Rear track – 1 790 mm. Front track – 1 800 mm. Minimum turning radius – 8 900 mm. The body platform is 5.10 cubic meters. The floor area is 8.72 square meters. Platform dimensions: width – 2 326 mm; length – 3 752 mm; height – 575 mm.

Complete sets and prices

Most car enthusiasts buy these trucks and make them into masterpieces. There are many photos of ZIL in the internet after its upgrade. You can buy a real Russian truck for a very modest price – from 35 – 50 000 Russian rubles. It is clear that their general and technical condition is not ideal, but to buy the necessary spare parts for the car is quite easy. Those cars that have remained in good condition are sold a little more expensive, the cost can reach up to 380,000 Russian rubles.

Complete sets

On the platform of the ZIL-130 truck, the automobile plant produced cars:

- ZIL-130G was produced for transportation of various overall cargoes and low-density elements, as well as for trailer towing, the total weight category of which does not exceed 8 tons. The machine itself is capable of carrying up to 6 tons of cargo (wheelbase 4 500 mm);

- ZIL-130B1 is a truck tractor of truck type, designed for towing different semi-trailers, the total weight of which (including the weight of the semi-trailer) is not more than 14.4 tons on the road surface (wheelbase 3 300 mm);

- ZIL-130D1 is a platform for construction of dump truck ZIL-MMZ-4502 and ZIL-MMZ-555; it perfectly coped with trailer transportation;

- ZIL-130D2 is a platform with a pneumatic output and a traction and coupling device, which is designed for construction of a dump truck-tractor ZIL-MMZ-45022;

- ZIL-130B2 – also a platform with pneumatic output, only on the trailer and towing hitch, which was designed for construction of dump truck ZIL-MMZ-554M for agriculture.

Except for those that were not mentioned, the production could produce complete sets of machines, which were assigned for operation in different climates. Any such 130th model has its own letter or numerical code. The machine’s operating time and reliability, as well as its economic performance, are largely dependent on the lapping of parts at the beginning of operation.

Initially, the plant planned to produce such models of standard equipment:

- ZIL-130A was a flatbed tractor for full-fledged operation with a trailer with a total weight of 8 tons. It is equipped with a combined braking crane, towing hitch and pneumatic and electric outputs to connect the braking system and electrical appliances of the trailer;

- ZIL-130G is a platform long wheelbase truck with 2 sectional side walls (wheelbase of 4 500 mm);

- ZIL-130B is a truck tractor of truck type with a short wheelbase (3 300 mm);

- ZIL-130WT is a truck tractor with a short wheelbase (33 cm) and a stronger rear axle;

- ZIL-130D – platform for dump truck of construction purpose with a short wheelbase (33 cm);

- ZIL-130B – platform for agricultural dump truck with a wheelbase of 3 800 mm.

- ZIL-MMZ-555 – dump truck with rear shipment. Built on the basis of ZIL-130D1. Due to the shortened base the truck has good maneuverability.

When the trucks were produced, a couple of significant upgrades of the ZIL-130 subdivision were carried out in 1966 and 1977. Following the latter, the radiator grille was changed. Various modifications of the grille could be equipped with a foreign-made engine at the customer’s request:

- Perkins345, 140 hp.

- Valmet 411BS, has 4 cylinders and operates at 125 hp.

- Leyland400, 6 cylinders and diesel fuel provide 135 horses.

A third non-leading axle can also be fitted to increase the payload. These machinations were carried out by subsidiaries outside the plant.

The pros and cons

Pluses cars

- Record low cost car;

- Low requirements for the necessary fuel;

- The small overall data allow to maneuver well even on city roads;

- Good maintainability;

- It is easy to find necessary details;

- Good cross-country ability and high road clearance;

- Hydraulic power steering.

Cons of a car

- Minimum car speed;

- Not a record load capacity of the machine;

- Year of manufacture;

- Many details often fail;

- The big expense of fuel;

- Lack of comfortable conditions in the cabin (by modern standards);

- Problems with the launch in the cold season;

- Low noise isolation and thermal insulation of the cabin;

- Uncomfortable chairs.

We sum up

For more than 40-year history the truck has proved itself as a fairly durable and reliable truck, which is easy to operate, easy to repair. Recognizable by all ZIL-130 or AMUR-53131 can still be found on Russian roads. A large number of modifications have made it popular in many areas from agricultural to military. It seems that it will drive on them for many more decades.

We advise you to read the article: ZIL – history of the autogiant