GAZ-AA

GAZ-AA is a truck of Nizhny Novgorod (1932) and later a truck of the Gorky Automobile Plant with a payload of 1,500 kg. The model is also called the “lorry and lorry”. The debut 5-year plan to improve the economy of the Union of Soviet Socialist Republics (1928-1932) made it possible to start a majestic development program.

The plan provided for the construction of more than 1,500 massive facilities, including hydroelectric power plants, metallurgical plants, automobile and tractor plants. In order to implement all these projects, transport was needed, and therefore it was not an easy strategic task to organize a full-scale production of trucks. The whole model range is GAZ.

Car history

By the end of the 1920s, only a couple of automobile companies were producing trucks in the Union in serial order: The first state automobile plant in Moscow (it used to be AMO), as well as the Third state automobile plant in Yaroslavl. But their speeds were not enough, as all two plants were created on the platform of pre-revolutionary capacities.

For example, by the beginning of the first five-year plan for the whole country there were only 1,500 cars. Therefore, no one was surprised that by the middle of the 1920s the Soviet government had planned to build the Union’s first car giant, the capacity of which would allow to produce about 100,000 vehicles per year.

When there was a lack of experience and technological resources, the best way to buy production abroad was to buy it. And the opinions of Russian specialists were aimed at the overseas country, or more precisely, Detroit. This settlement, located in the north of America, was for the builders of socialism a model automobile grandeur, the city of the future, in which the settlers live and work, subject to a single and general functional plan.

This is exactly the format in which the Russian car giant was also dreaming of building. They wanted to build residential neighborhoods for employees and design all the infrastructure that accompanied them. As a result of negotiations, General Motors decided not to take part in the project, so the only variation was Ford. This option satisfied the USSR quite well.

Henry Ford’s name itself, along with his automobile empire, was often associated with technological solutions and rationality. In addition, this company was well known in the Union of Soviet Socialist Republics, because although not huge, but still stable purchases of “Fordovsky” cars were made since 1909. In addition, for the needs of our country, the best suited to the needs of the new Ford base, which in 1927-1928 replaced the previous generation of “T”. The Ford-A car and the Ford-AA lorry were simple, unpretentious, inexpensive and, very importantly, were well unified in design.

According to the technical agreement, the USSR signed a contract with Ford on May 31, 1929. It was planned to build a motor city near Nizhny Novgorod, near the village of Monastyrka, where the navigable rivers (Oka and Volga) merged. The agreement on the construction of the enterprise together with the town for the Union of Soviet Socialist Republics working there was signed with Austin Company in Cleveland.

The USSR began to cooperate with the famous American company Ford. As a result, the world saw a 1.5-ton truck GAZ-AA, which was similar to an American.

In addition to the construction of the automobile giant, the agreement with the company Ford provided for the presence of operational construction of a pair of car assembly plants, which will be located in Nizhny Novgorod and Moscow. They planned to assemble Ford cars from ready-made car kits, because the contract of the Union of Soviet Socialist Republics was to buy 72,000 car kits.

These assembly shops provided an opportunity to start production of machines before the end of the construction of the plant in Nizhny Novgorod and were such factories for production training for those who worked there. In order to build and equip its branches, the company from America decided to attract the already popular in Russia construction company Albert Kahn, Inc.

Already at the beginning of 1929, the share of the area of the agricultural transport company “Gudok Oktyabrya”, which were located in the city of Kanavin, decided to take away for the construction of the first car assembly plant. Already in the winter of the next year (1930) it began to assemble the debut Ford-AAA trucks from American car kits.

Already by the end of the same year, passenger cars, along with cargo “fords”, began to be produced from the primary conveyor of the automobile plant in Moscow. However, Nizhny Novgorod’s desire for a motor-city began to melt. Partly, it happened because of the small project estimate, as well as because of the enthusiasm of the manufacturers, which interesting method was able to harmonize with the carelessness and lack of agreement on the decisions and works of many administrative bodies.

The largest European automobile company was able to build the largest in the European countries at the right time, but the result was far from the “air” dreams of the industrial camp of the future. The new construction near Monastyrka was nicknamed Sotsgorod among the people, and in 2 years it acquired the official status of the Avtozavodsky district of Nizhny Novgorod.

While the 2nd half of the first month of 1932 was going on, the enterprise, prepared for the start of the design capacity, managed to master the production of the cylinder block, together with the crankshaft, frame spars and other details. Due to the lack of constancy in the delivery of components from the neighbors (to be more precise, sheet steel), the cabins of “pre-production” began to be assembled using plywood.

On January 29 of the same year, NAZ-AA’s debut cars were manufactured from the company’s conveyor belt in Nizhny Novgorod. In October (7th day) Nizhny Novgorod was renamed into Gorky, so the name of the car was changed. By the end of 1932, the production of trucks of the Gorki Motor Works was about 60 trucks every day. The name of the truck became GAZ-AA.

The car GAZ AA turned out to be reliable and enduring, and lost, except to one real rival in the car market of the USSR – Moscow tri-tonnage ZIS-5. However, the automobile enterprise in Gorky had much more production capacities than VMS.

Therefore, the lorry was supposed to become a “multifunctional soldier” of the national economy, and Gorky specialists designed various “civilian” and “military” vehicles and improved the existing standard vehicles. In order to check the weak points of the AA lorry, at the end of the 32nd year the trucks participated in a test run from Nizhny Novgorod to Moscow and back. Six months later (in 1933) they took part in the summer extreme “Karakum” run.

The lion’s share of standard breakdowns was explained by the underestimated quality of components that were supplied by conjugators. While it was 1933, car factories in Moscow and Gorky fully used the arsenal of car kits from America and migrated to the creation of machines from spare parts of its production.

Three years later, the Gorky Automobile Plant managed to master the production of a new power unit GAZ-M (50 horsepower), which was a forced version of the GAZ-A engine. One and a half tons were equipped with the last engine in 1938.

At the same time, a new, synchronized steering system was released, along with the reinforcement of the rear mounted springs. This modification was named GAZ-MM. The Gorky Automobile Plant assembled the last lorry on October 10, 1949.

Ulyanovsk Automobile Plant, which assembled MM from the 47th, stopped assembling these models only by the 51st year. Since the 32nd year, before the start of the hostilities, the KIM enterprise, together with the assembly plant in Rostov-on-Don, produced more than 800,000 1.5 tons of AA and MM trucks. During the wartime, GAZ produced 102,300 trucks.

Appearance

Since the autumn of the 40th, it has been equipped with a powerful towing device along with the accessories for attaching a spare wheel of another mechanism. The car’s material was changed as soon as the Great Patriotic War began. If to tell concerning metal it began to be saved, therefore the forward part in due course has lost all details which were not considered as urgently needy.

The wings, which were angular, began to bend from the roofing iron, and the roof, along with the doors, was made with the use of tarpaulins. The headlamp, along with the janitor, was installed only from the driver’s side, and the front brakes, along with the silencer and bumper, were not installed at all.

Since 1943, the tarpaulin valves of the side parts of the cabin have been replaced by wide wooden doors. Simplified modification of GAZ-MM continued to be produced even after the end of hostilities, but the trucks received full metal doors, silencers, front brakes, a bumper and a pair of headlights. The tarpaulin of the rear wall of the cabin had a rectangular window. This is clearly visible in the photo.

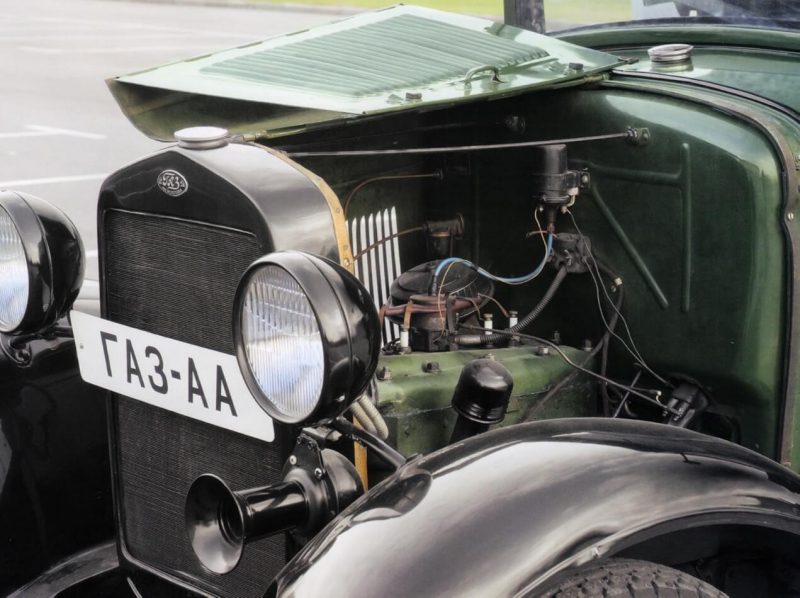

GAZ-AA was quite simple, but successful and technologically advanced truck, which was not picky and could not work with the highest quality fuel. The front part of the “Lawn” was quite simple. There was a simple bumper, a pair of headlights and a large rectangular grille. Two front lights were mounted on the wings of the wheels and the front hood. Underneath one of the lamps there was an acoustic signal.

The hood covers opened like seagull wings, providing a convenient space for repair of the power unit. Nearby was a 40 litre fuel tank. The spare wheel was located under the frame on the rear of the chassis. The side was occupied by a door with smooth wheel wings and a comfortable footrest. Also, the wooden body smoothly moved from the side to the stern. Side and rear sides were hinged. Also on the rear of the vehicle, on the left side, it was possible to find the rear lighting.

Specifications

Powertrain

For all its simple qualities, GAZ-AA was technically quite perfect. It had a four-cylinder engine with a working volume of 3,285 liters and about 42 horses. The same engine was installed on the passenger car GAZ-A.

It was a four-stroke in-line carburettor lower-valve water-cooled carburettor. Fuel consumption per 100 km at full load (when driving on the highway) was 18.5 liters. Maximum speed is 70 km/h.

Transmission

The engine torque was transmitted to the drive axle by means of a single-plate dry friction clutch and a four-speed manual gearbox. It is a three-way mechanism and has four forward and one reverse gear. The gearbox has not been synchronized. Wheel drive is rear.

Suspension

It was represented by dependent mechanisms. The front wheels were suspended from one transversely mounted semi-elliptic spring, where there were push rods that could transfer the load on the frame. Rear mounted wheels were mounted on a pair of longitudinal cantilever springs and were deprived of any shock absorbers. As a design feature, the rear suspension mechanism was used together with the transmission, where a cardan shaft was used as the longitudinal thrust, which was supported by a bronze bushing.

Brake system

The service brake had a mechanical drive. The brakes were foot-type with pad mechanisms. All wheels were equipped with drum brakes.

Steering control

The steering mechanism had a worm and a double roller and a gear ratio of 16.6.

The pros and cons

Pluses cars

- High-quality and reliable body metal;

- Good ground clearance height;

- Excellent cross-country ability of the car;

- Small size of the truck;

- There is a windscreen wiper of the windscreen (from the driver’s side);

- Pretentiousness in fuel;

- Clear service;

- The American roots of company Ford;

- The windshield is moved out;

- It is possible to transport trailers.

Cons of a car

- No hydraulic power steering and no braking system;

- No steering wheel or sofa adjustments;

- Ascetic interior;

- Weak powertrain;

- Simple and cold cabin;

- Dependent suspension;

- High fuel consumption;

- Small transported weight;

- Absence at least any comfort.

We sum up

Any merger of Russian automobile companies with foreign companies has always been in favor of the domestic automotive industry, and GAZ-AAA is no exception. Its similarity with foreign variations can be seen in the photo. The car turned out to be surprisingly simple, but functional and in demand.

At that time, there were no environmental regulations, so the fuel consumption of its weak power plant was 20 liters per 100 kilometers. The appearance of the car was very simple, and there was not even a hint of sophistication, because we should not forget the years of its production and the purpose of production.

It was supposed to be faithful and true on almost all road surfaces. The truck received a good ground clearance height, rear-wheel drive and a payload of 1,500 kg. This was not a record, but in pre-war times and during the fighting the Union of Socialist Republics was in dire need of light vehicles. Inside the cab only two people, including the driver, could fit. The interior was also very simple, which once again emphasized the purpose of the machine – to work.

Russian specialists were able to take the best of the American famous company, which made it possible to make a successful car. Decades later, the Gorky Automobile Plant will again resort to the assistance and purchase of foreign vehicles and spare parts. Today you can find this model at private collectors and at the museum.

We advise you to read the article: GAZ – history of car production.